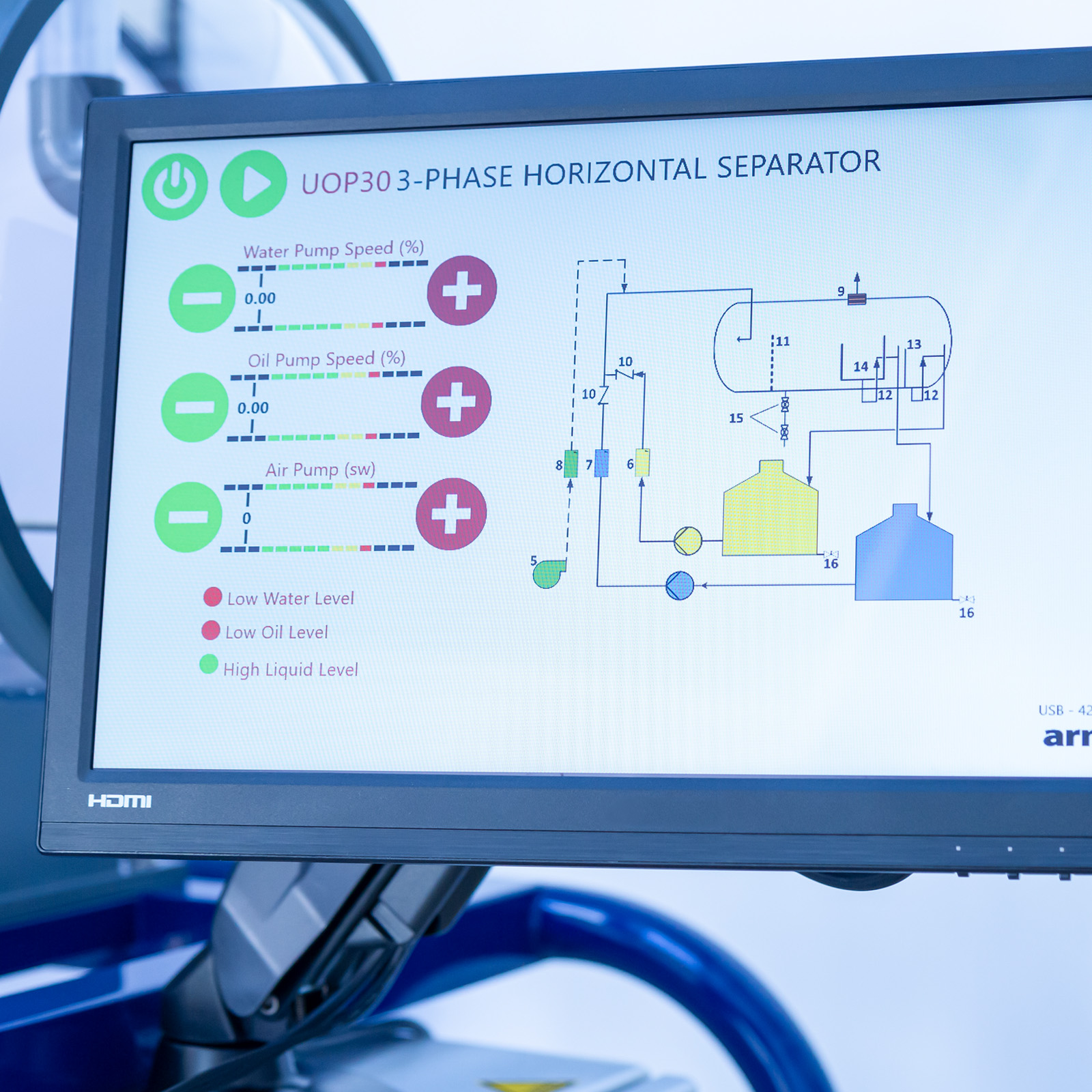

UOP30 – 3-Phase Horizontal Separator

The Armfield 3-Phase Horizontal Separator is a small-scale unit capable of demonstrating the principles and operation of gravity separation and the effect of viscosity, flow characteristics and density difference on separation. The Armfield UOP30 comes with two horizontal separator configurations, making the UOP30 a versatile teaching unit.

Description

The Armfield 3-Phase Horizontal Separator is a small-scale unit capable of demonstrating the principles and operation of gravity separation and the effect of viscosity, flow characteristics and density difference on separation. The Armfield UOP30 comes with two horizontal separator configurations, making the UOP30 a versatile teaching unit.

The separation of two immiscible liquids and a gas using density difference is one of the most important process operations in the oil and gas industry. Examples include separation of produced water and condensate from gas and the separation of gas and produced water from crude oil.

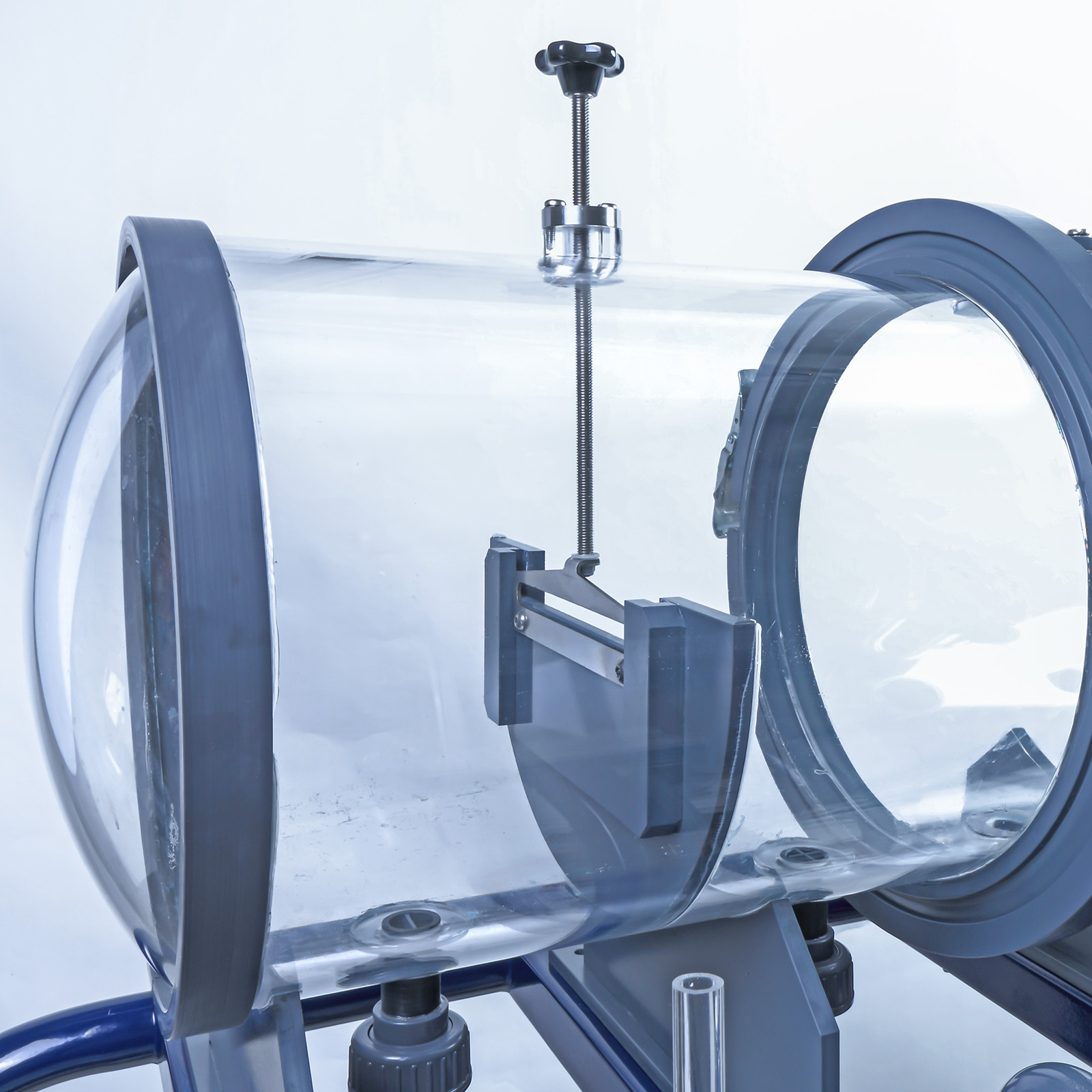

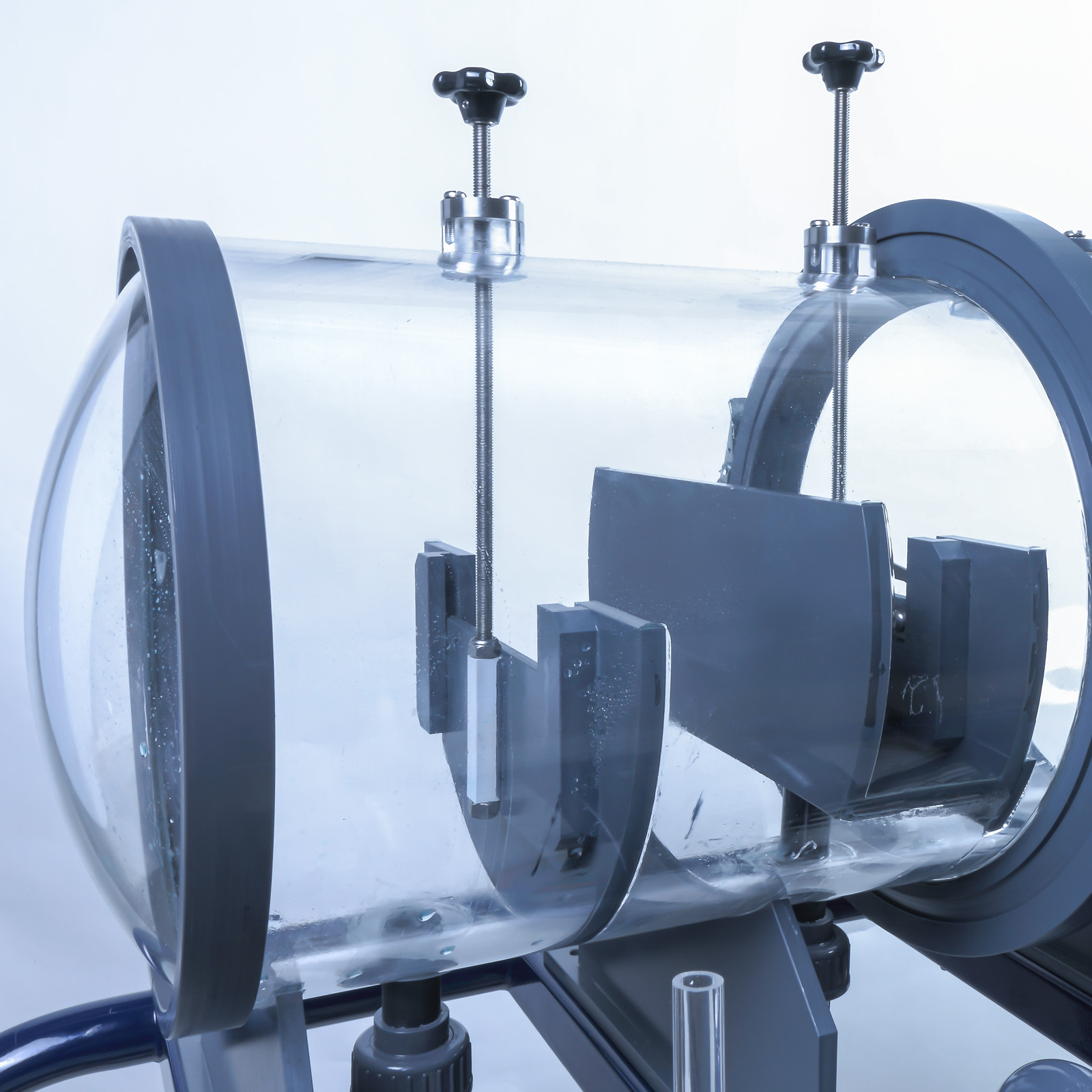

A combination of refined oil, water and air enters the vessel, the flow is directed to the spherical end of the vessel where primary separation occurs and then flows through the vessel where it meets the coalescer.

At the secondary separating section, the fluids are allowed to slow down and separate by gravity. The water, being the heaviest in mass, stays at the bottom while the oil floats on top and the gas occupies the void space in the vessel.

Technical Specifications

The Armfield 3-Phase Horizontal Separator has been designed in accordance with API 12J and CE requirements.

Clear acrylic vessel: 300mm x 900mm

Water flow meter range: 0-25 l/min

Refined oil flow meter range: 0-25 l/min

Airflow meter: 0-10 l/min

Feed tanks capacity: 50l

Water pump range: 0-15 l/min

Refined oil: 0-9 l/min

Features & Benefits

Features

- Computer controlled with integrated data logging

- Continuous recycling of feed

- Two separator interchangeable designs supplied as standard (weir and Bucket & Weir design)

- Visual demonstration of the entire separation process

- Adjustable interface & level controller

- Emulsion chemistry possible (stable and unstable emulsion)

- Compatible with different feed (use of different oils with varied viscosity and density)

- Compact / self-contained unit*

- Adjustable weir and bucket weir heights

- Water and oil non-return valves for safe operation of the unit

- Optical liquid level sensors

- Coalescer

Benefits

- Enables the evaluation of the design principles and controlling parameters of three-phase separation

- Enables study and investigation of the separation of two immiscible liquids

- Clear acrylic vessel and pipework for visual demonstration of entire process

- Versatile unit with two separator design configurations supplied as standard

- Rapid removal of separator design configurations to enable cleaning and quick changes in experimentation

- User friendly control of flow rates and levels within the vessel

- Fine control of weir and bucket heights

- User-friendly adjustment of level and interface heights

- Learn basic principles of control and operation of a three-phase separator

- Effect of varying operating conditions on separation

- Effect of step change on overall process

- Effect of gravity separation on small ΔSG

- Effect of continuous-phase medium on droplet size and separation

- Variation of water cut to show the effect on separation and residence time

- Effect of flow rate on emulsion formation

- Evaluation of emulsion chemistry possible (stable & unstable emulsion)

- Effect of water-oil ratio on residence time

- The effect of density difference on separation

- Two-design configuration supplied as standard (interface controller & weir and bucket & weir)

- Compact / self-contained* floor-standing unit

- Computer controlled via optional LCD touchscreen (or user-supplied PC with USB interface)

- Integrated data logging

- Clear acrylic vessel for complete visualisation of the process (300mm x 900mm)

- Adjustable interface controller to suit different oils

- Adjustable bucket weir height

- Adjustable weir height enables compatibility with a variety of oils

- Mist extractor (demister pad) – Small scale and mounted externally to the main vessel, does not obscure the visibility of the separation process

- Optical liquid level sensors x3

- Colaescer x2

- Feed tanks x2

- Drain connection with valve for draining / cleaning the unit

- Electronic flow meters x3

- Temperature sensors x3

- Non-return valves x2

- Feed pumps x3

- Mains isolating switch

- Electric control panel in main cabinet with earth leakage circuit breaker

- Anti-syphon system on the air-stream

- A comprehensive instruction manual with details of installation, operating procedures and sample experiments

*When used with the optional LCD touchscreen

Single phase mains electrical supply:

UOP30-A: 220-240V / 1ph / 50Hz

UOP30-B: 120V / 1ph / 60Hz

UOP30-G: 220V / 1ph / 60Hz

Cold water: For initial fill prior to use and as required during the process

Oil: Refined oil

For UOP30 without optional LCD touchscreen: A PC (not supplied) running Windows 7 or later, with a USB port.

PACKED AND CRATED SHIPPING SPECIFICATIONS

UOP30 Unit

Volume: 2.45m³

Gross Weight: 230Kg

Armsoft LCD

Volume: 0.07m³

Gross Weight: 2.6Kg

Length: 1.80m

Width: 1.00m

Height: 1.40m

- UOP30-A

- UOP30-B

- UOP30-G

- ArmBus-LCD -15.6: Optional LCD touchscreen